Up Next

Four teams have introduced modifications either to the halo fairing or the cockpit headrest in recent races, underlining how aerodynamically sensitive the area around the driver’s head is.

Mercedes added what it described as a pair of “small flick” vanes behind the halo in Shanghai, designed to control the airflow as it passes out of the cockpit - and therefore improve the airflow to the rear wing.

Williams made a small modification to the shape of the fairing on the central part of the halo where it separates into the two parts that curve outwards from the cockpit. The point of it is to improve aero efficiency and the airflow to the rear wing and beam wing.

And RB modified the shape of the headrest behind the driver's head on the basis that it reduced airflow separation.

This was followed by Alpine realigning its halo vanes on either side of its cockpit in Monaco to better distribute airflow to the rear wing and beam wing at the back of the car.

None of these changes are visibly big, but the fact four teams made modifications proves how much there is to gain in compensating for the inconvenience of having to accommodate the driver’s head. And this has been a significant challenge for many years.

Looking back to 1996, F1 introduced regulations requiring a compulsory headrest that went around the sides of the driver’s helmet to protect their heads from lateral impacts. That led to some very different solutions being introduced.

Ross Brawn, then at Benetton, wasn’t very complimentary about the design that Adrian Newey at Williams and we at Jordan came up with. By comparison, Brawn’s Benetton and John Barnard’s Ferrari resembled more of a rubbish skip in this area!

What we came up with meant all the teams started looking closely at the airflow around the driver's head and the airbox opening for 1997. It was important then, and it’s the same now but it’s interesting to see how trends carry forward even when the regulations are very different.

With the normally-aspirated engines of the 1990s, you could get a positive pressure within the airbox of something like 30mbs.

If you had a decent airbox design, that equated to something like 25hp so it was well worth having. It ensured the engine was getting as much airflow as it could handle. And when it comes to engines, the more air you have the more powerful the all-important detonations that create the power. Put simply, you get a bigger bang for your buck.

As normal during that era Williams did a slightly better job on it than we did, but it had the benefit of knowing who its drivers were going to be fairly early in the car design. We were never sure until more or less the first race!

When you define this area, you really need to know the position of the driver’s head. If you eventually end up with a driver that is 5 centimetres taller or short in the leg and long in the body, it just doesn't quite look as well-detailed.

On the Williams, the red arrows show the flow going into the airbox and the green arrows the flow further down going around the side of the driver’s head. The yellow arrows are the flow when it spills around the sides of the intake.

As you can see on the Jordan, it is very similar - perhaps just not quite as detailed.

It wasn't just a matter of making the opening bigger and you achieved a higher pressure and more power. When you got to that sort of pressure, the excess flow would spill outwards around the leading edge of the intake.

The actual firing order of the engine – so the sequence in which the cylinders are ignited - was also important to how the pulsing in the airbox was distributed, and with it the fuel transfer from cylinder to cylinder.

Today’s engines have a turbo, which adds positive pressure on the engine’s intake system. The actual intake is not so critical to the engine performance, but the turbulence from the driver’s helmet and the effect that has on whatever is being cooled by the airflow going into the rollover bar intake is.

Also when the flow blocks off or the turbo is not requiring maximum flow, the spillage can easily cause the driver’s helmet to buffet from the turbulence. It can also reduce the efficiency of the downforce produced by the rear wing. Buffeting of the helmet is something George Russell has complained about this season.

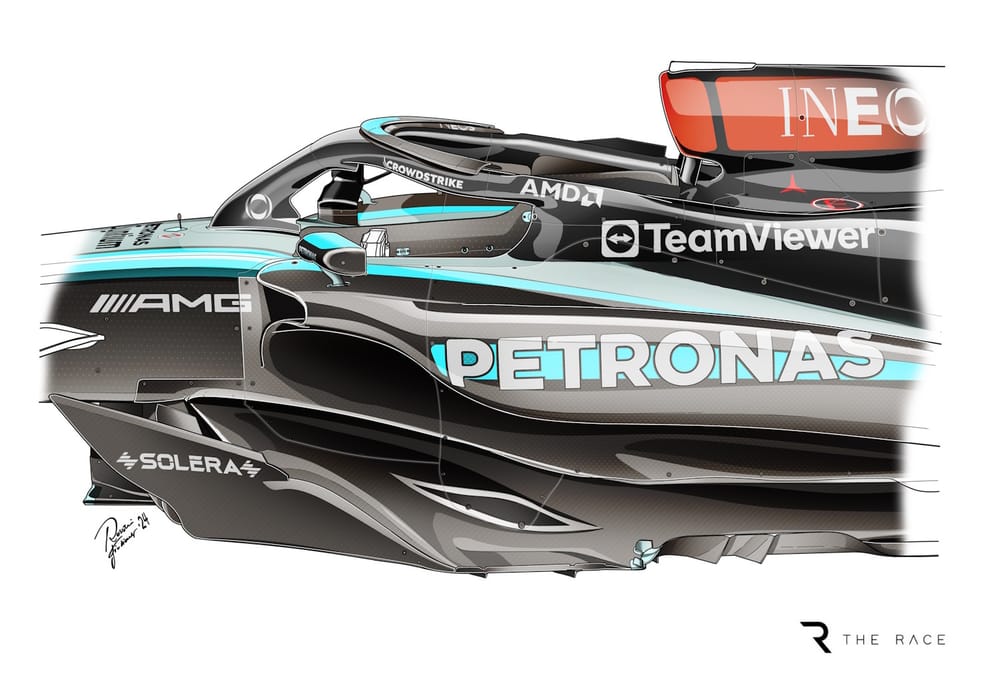

A close-up here of Russell in his Mercedes shows the headrest side and the halo rear mounting defines the blockage beside the driver's head. You can use a limited-size fairing around the halo’s main tubular structure so it enables you to redirect the airflow slightly.

However, the helmet is very similar to our 96/97 versions and that dictates the flow structure coming off it and around the headrest.

I have used the same colours to highlight the flow. The main difference is how the flow comes off the side area of the headrest just in front of the TeamViewer decal. The rest is very similar.

If you were trying to take the next step in managing the flow around the driver’s helmet, when the intake starts to block off, what better way of doing it than putting some cooling duct openings in that area?

Those, combined with the fact there is a low-pressure area at the exit of these ducts, mean that the flow through there will be much more consistent through the speed range than just introducing it into the main stream airflow.

This shot of the Red Bull with its inlets highlighted in green shows just that.

It just shows how every single part of the car plays a crucial role in the aerodynamic performance.

The difference between getting the details of the headrest, the driver position and the halo fairings right or wrong will be significant laptime so expect plenty more developments in this area.